Ever since the birth of the first commercial computers, cooling has always been an issue. While the first chips hardly required significant cooling, the rapid advancements of the past few decades and the high commercial demand led to significant research and development efforts placed towards the improvement of cooling solutions and methods.

Semiconductor cooling, particularly cooling for enthusiast PCs, has come a long way, with hundreds of advanced coolers available and liquid cooling no longer reserved only for hardcore enthusiasts. With the mass production and competitive pricing of all-in-one (AIO) liquid coolers, basic liquid cooling systems can be easily found inside typical living room PCs. Competitive overclockers still experiment and use some extreme cooling methods (e.g. liquid nitrogen), but such sub-zero methods usually can only be used (very) temporarily.

One of the PC CPU cooling methods that was originally explored by overclockers in the 90’s is the use of a thermoelectric (TEC) cooler. These devices had a few advantages but also crippling disadvantages that prevented the technology from finding wide commercial use in consumer PCs. There have been a handful of commercial CPU coolers with a TEC pre-installed many years ago but not a single one of them found commercial success.

Today we are having our first contact with Phononic, a newcomer in the PC cooling market. The company was founded back in 2009, is based in North Carolina and is focused on the research and development of advanced cooling and refrigeration solutions. Their first and currently only CPU cooler, the HEX 2.0, is a very surprising and unique product. It looks like a relatively small tower cooler, yet it has an integrated electronically controlled TEC heat pump that is even partially controllable via software.

Simply put, a TEC is two metallic plates which when current is applied, one side heats up and the other side cools down. The cool side is typically the one on the CPU, with a sufficient cooling system to remove the heat from the top side (previously, strong air or water cooling was needed, as these systems have an efficiency rating that the hot side produces more heat than the standard CPU. So the TEC requires massive regular cooling alongside it to get the advantages.

The technical description is that the two metallic with electronic junctions sandwiched between them. When electrical energy in the form of DC current is introduced, the device pumps thermal energy from one side to the other (Peltier effect), creating a temperature difference between the two sides. There are however a few problems when working with TECs:

1. Condensation. A typical TEC can produce a temperature difference of up to 70 °C between its cold and hot side. Assuming that a heatsink is mounted to the hot side and that it is capable to maintain a near-room temperature, the cold side of an uncontrolled TEC can be significantly colder than its ambient surroundings. That will cause condensation, which will be disastrous inside a PC.

2. Efficiency. TECs are generally inefficient, with an efficiency usually lower than 15%, which means that they consume disproportionally high amounts of electrical energy for the work they actually offer.

3. The electrical energy losses that the TEC inserts are converted directly to thermal energy and transferred to its hot side. Therefore, the heatsink has to deal with the thermal load of the system plus the energy losses of the TEC, increasing the size and performance requirements.

All that being said, any company willing to attempt the challenges of the physics behind TECs is welcome to try, especially if it ends up as a commercial product for home PCs. Hence why we got the Hex 2.0 in for review.

We received the Hex 2.0 in a well-designed and very sturdy cardboard box. The walls of the box are very thick and the cooler itself is protected by several layers of cardboard, providing excellent shipping protection.

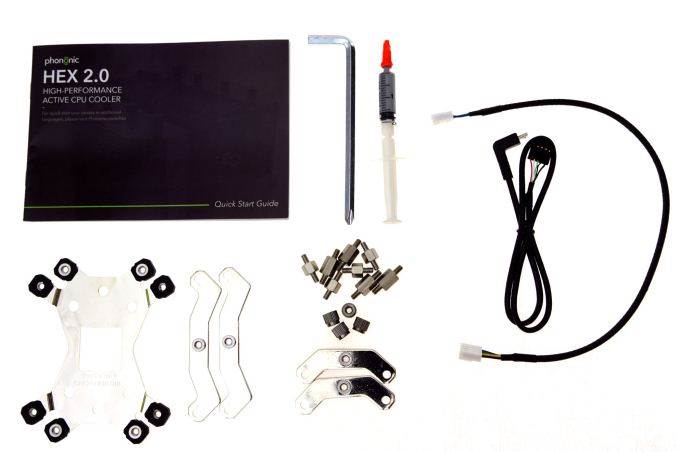

Alongside with the cooler, Phononic supplies the necessary mounting hardware, the required cables, a simple but useful guide, a simple screwdriver tool and a generous amount of thermal grease. The thermal grease that the company supplies should be enough for perhaps a dozen applications.

If not for the 6-pin PCI Express power connector at its side, the HEX 2.0 could be easily mistaken for a simple medium-sized tower cooler. It is only 12.5 cm tall and should fit in many narrow cases, where several top-tier air coolers cannot. The HEX 2.0 is a dual-tower design, with four heatpipes transferring the thermal energy from the CPU to two arrays of aluminum fins, and with the fan placed between the two fin arrays. In this case, Phononic also placed the control electronics in between the arrays and covered everything with a neat plastic frame.

Phononic put a significant amount of effort in the aesthetic design of the Hex 2.0. Both the aluminum fins and the copper heatpipes of the cooler are chromed. The tips of the heatpipes extruding above the fin arrays are perfectly symmetrical. Phononic also placed a very strong RGB LED inside the company logo beneath the connectors, the color of which is selectable via the control software (green by default).

The frame can be partially removed, revealing the 92 mm cooling fan and providing access to the mounting screws. It will have to come off in order to install the cooler, but it is not necessary to completely remove the fan as well.Note that the fan can be replaced but needs to be inserted in a specific direction, as marked on the base of the cooler. Phononic is using a very high quality Sanyo Denki San Ace 9S0912P4F011 fan. Even though it is part of Sanyo’s “Silent” range, this fan has a maximum speed of 2650 RPM and will be quite loud should it operate at maximum speed.

The base of the cooler consists of a chromed copper plate that comes in contact with the CPU and a black aluminum frame that provides mechanical cohesion. Its chromed copper base is virtually a nearly perfect mirror. The TEC and the heatpipes are sandwiches between the copper plate and the aluminum frame. A temperature sensor can also be seen attached to one of the screws holding the base together.

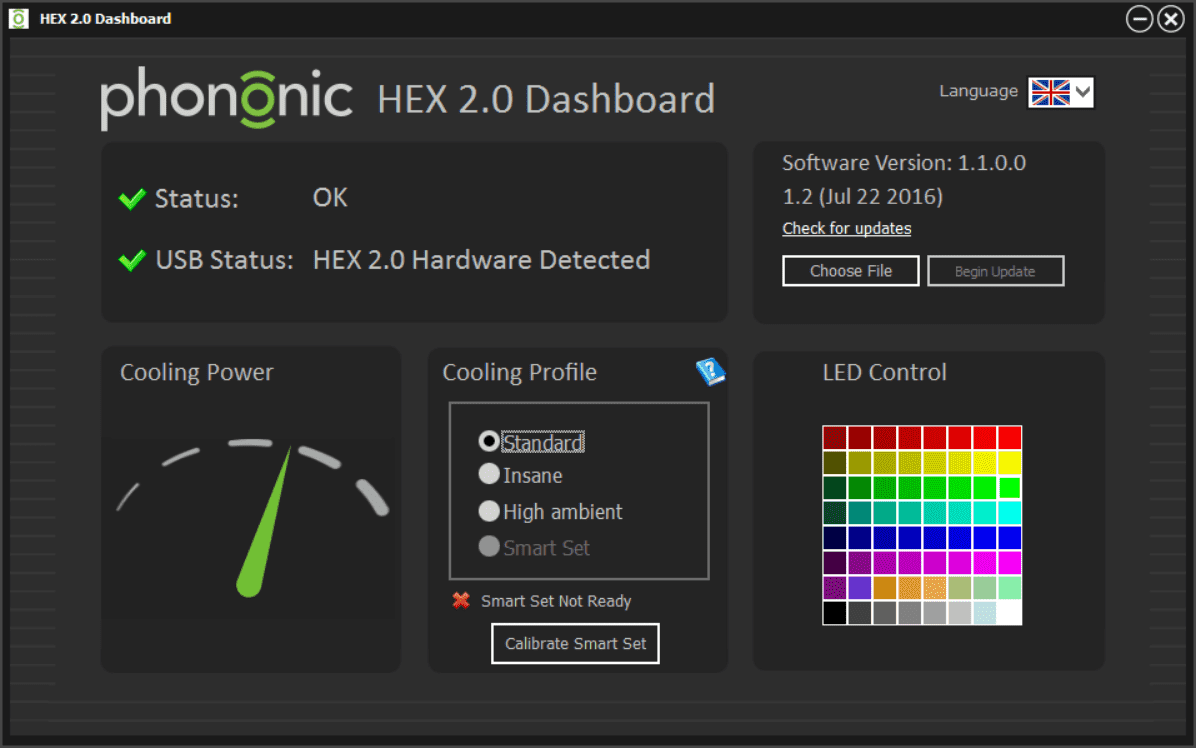

The HEX 2.0 Dashboard software is very straightforward and lightweight. Not even an installation is required, the software is a simple executable file that can be launched instantly once downloaded.

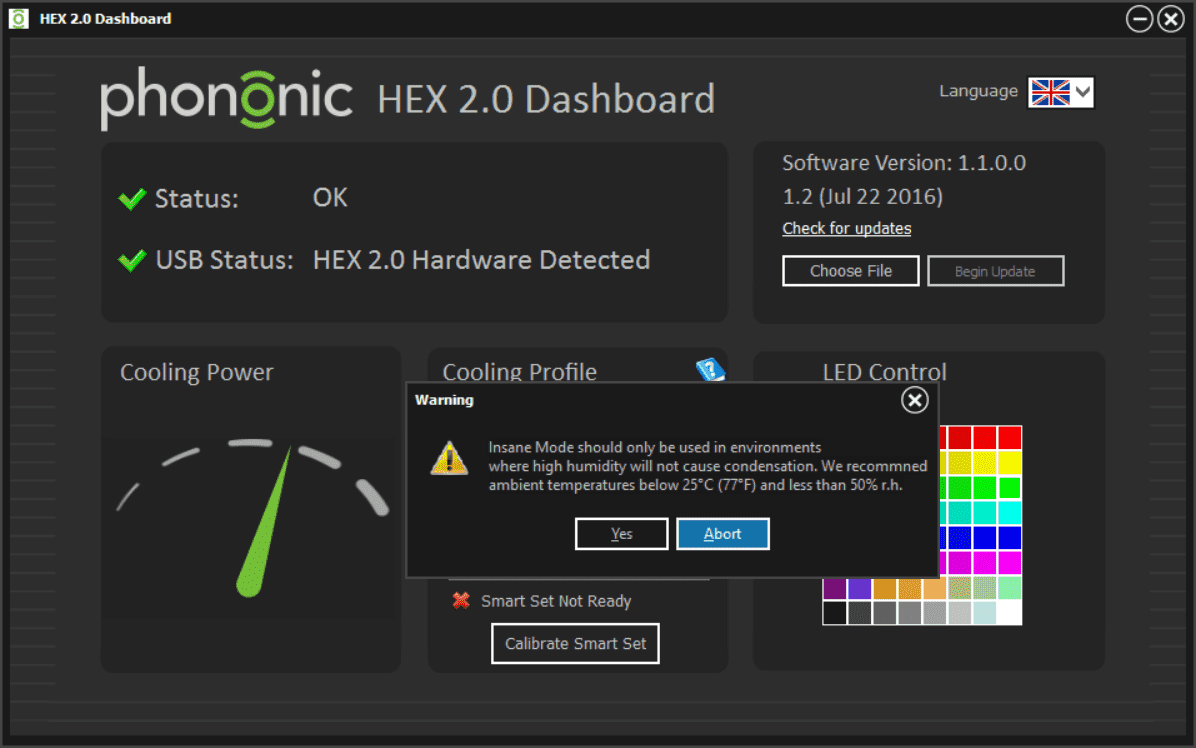

To the left of the screen, the user can check the “cooling power”, which indicates the power of the TEC. There are three cooling profiles to choose from: standard, insane and high ambient. The standard mode addresses most users, where the firmware of the cooler will be adjusting the power of the TEC according to the thermal load. Setting the cooler to insane mode will lock the TEC at maximum power and, as the warning message says, it can cause condensation under certain conditions. High ambient mode sets the TEC to activate at higher thermal loads only to prevent condensation in very humid environments.

Although the testing of a cooler appears to be a simple task, that could not be much further from the truth. Proper thermal testing cannot be performed with a cooler mounted on a single chip, for multiple reasons. Some of these reasons include the instability of the thermal load and the inability to fully control and or monitor it, as well as the inaccuracy of the chip-integrated sensors. It is also impossible to compare results taken on different chips, let alone entirely different systems, which is a great problem when testing computer coolers, as the hardware changes every several months. Finally, testing a cooler on a typical system prevents the tester from assessing the most vital characteristic of a cooler, its absolute thermal resistance.

The absolute thermal resistance defines the absolute performance of a heatsink by indicating the temperature rise per unit of power, in our case in degrees Celsius per Watt (°C/W). In layman’s terms, if the thermal resistance of a heatsink is known, the user can assess the highest possible temperature rise of a chip over ambient by simply multiplying the maximum thermal design power (TDP) rating of the chip with it. Extracting the absolute thermal resistance of a cooler however is no simple task, as the load has to be perfectly even, steady and variable, as the thermal resistance also varies depending on the magnitude of the thermal load. Therefore, even if it would be possible to assess the thermal resistance of a cooler while it is mounted on a working chip, it would not suffice, as a large change of the thermal load can yield much different results.

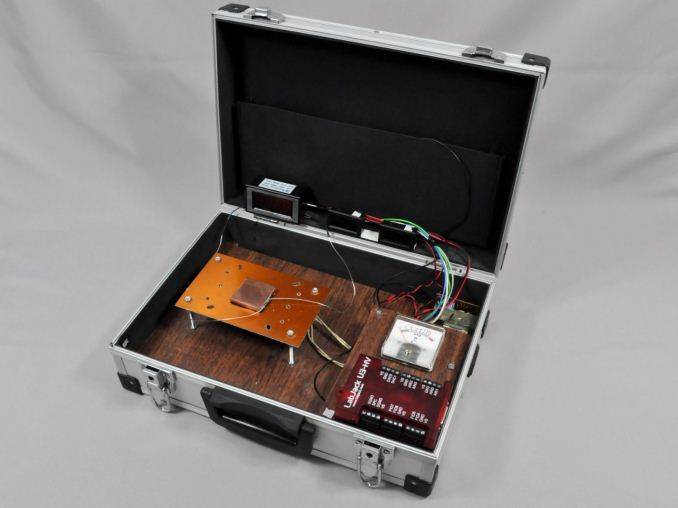

Appropriate thermal testing requires the creation of a proper testing station and the use of laboratory-grade equipment. Therefore, we created a thermal testing platform with a fully controllable thermal energy source that may be used to test any kind of cooler, regardless of its design and or compatibility. The thermal cartridge inside the core of our testing station can have its power adjusted between 60 W and 340 W, in 2 W increments (and it never throttles). Furthermore, monitoring and logging of the testing process via software minimizes the possibility of human errors during testing. A multifunction data acquisition module (DAQ) is responsible for the automatic or the manual control of the testing equipment, the acquisition of the ambient and the in-core temperatures via PT100 sensors, the logging of the test results and the mathematical extraction of performance figures.

Finally, as noise measurements are a bit tricky, their measurement is being performed only manually. Fans can have significant variations in speed from their rated values, thus their actual speed during the thermal testing is being acquired via a laser tachometer. The fans (and pumps, when applicable) are being powered via an…

![[Video] Reimagined for Orchestra, ‘Over the Horizon 2026’](https://loginby.com/itnews/wp-content/uploads/2026/02/Video-Reimagined-for-Orchestra-‘Over-the-Horizon-2026’-100x75.jpg)